In the fast-paced world of product development, the gap between a digital design and a physical part can be filled with delays, uncertainty, and costly revisions. For modern engineers and designers, efficiency is paramount. This is where Xometry, a global leader in on-demand manufacturing, steps in—not just as a manufacturer, but as a technology partner. Xometry offers a powerful suite of tools designed to integrate seamlessly into your workflow, streamlining everything from initial quoting to final production.

This comprehensive guide will explore the full spectrum of xometry design resources, from powerful CAD add-ins to a robust API that puts the power of a global manufacturing network at your fingertips. Whether you’re a solo inventor or part of a large enterprise engineering team, these tools are built to help you innovate faster, design smarter, and bring your ideas to life with unprecedented ease.

Table of Contents

- Integrated Design at Your Fingertips: Xometry CAD Add-ins

- Automating Your Workflow: An Introduction to the Xometry API

- Getting Started: A Practical Guide to Xometry API Integration

- A Closer Look: Key Features of the Xometry API

- Beyond the Code: Other Essential Design Resources

- Frequently Asked Questions

Integrated Design at Your Fingertips: Xometry CAD Add-ins

One of the most significant hurdles in the design process is leaving your native CAD environment to get quotes or manufacturability feedback. Xometry eliminates this friction through its powerful xometry cad integration, which brings its Instant Quoting Engine directly into your design software. This means you can get real-time price quotes, lead time information, and critical Design for Manufacturability (DFM) feedback without ever exporting a file.

These add-ins are invaluable tools for optimizing designs on the fly. By seeing the cost and manufacturing implications of every design choice instantly, engineers can make more informed decisions, reduce downstream errors, and accelerate their development cycle.

Xometry offers dedicated add-ins for the industry’s leading CAD platforms:

- The xometry solidworks add-in is a must-have for SOLIDWORKS users, embedding quoting and DFM analysis directly into the task pane.

- Similarly, the xometry inventor add-in provides the same powerful functionality for professionals working within Autodesk Inventor.

- For those using cloud-based design tools, the xometry fusion 360 add-in ensures a seamless connection to Xometry’s manufacturing services.

Automating Your Workflow: An Introduction to the Xometry API

While CAD add-ins are perfect for individual designers, larger teams and enterprises often require deeper, more scalable solutions. This is where the xometry api comes in, offering a programmatic way to access Xometry’s vast manufacturing network and quoting intelligence. But what is the xometry api? In simple terms, it’s a set of tools that allows your own software applications to communicate directly with Xometry’s platform.

This opens the door to powerful automation and integration possibilities. Imagine building a custom procurement portal for your company, embedding instant quoting into your PLM system, or creating a unique workflow that automatically sources parts as designs are approved. The API makes all of this possible, transforming Xometry into a true manufacturing as a service api.

For businesses looking to streamline their supply chain and procurement processes, the API is an essential resource. It provides a direct path to automated quoting, reducing manual effort and accelerating time-to-market. This makes it one of the most powerful tools available from xometry for engineers and procurement professionals alike.

Getting Started: A Practical Guide to Xometry API Integration

Embarking on your xometry api integration journey is a straightforward process, thanks to excellent support and clear resources. The central hub for all development is the xometry developer portal, where you can find everything you need to begin.

Here’s a simple breakdown of how to use xometry api:

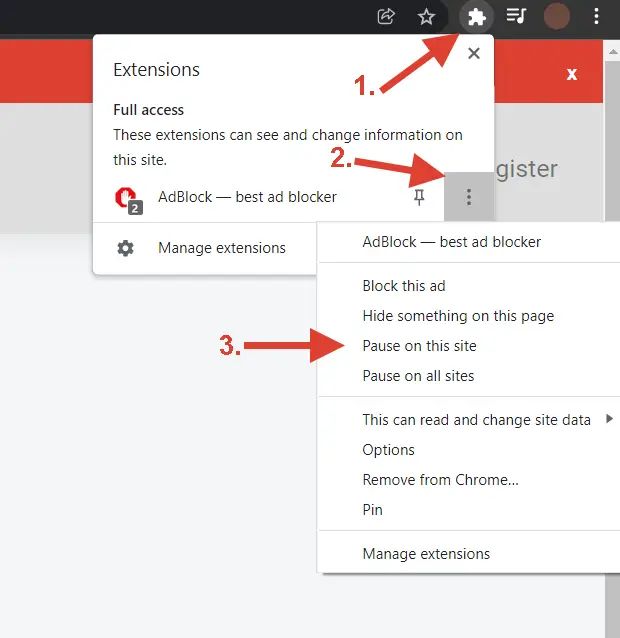

- Get Your Key: The first step is to sign up on the developer portal to receive your unique xometry api key. This key authenticates your requests and grants you access to the API’s functionalities.

- Consult the Documentation: The portal hosts comprehensive xometry api documentation that outlines every endpoint, parameter, and request/response format. This is your primary guide for understanding the API’s capabilities.

- Explore Examples: To accelerate your development, the portal provides numerous xometry api examples in various programming languages. These code snippets offer a practical starting point for building your first requests.

By following these steps, developers can quickly integrate Xometry’s quoting and ordering power into any internal or customer-facing application.

A Closer Look: Key Features of the Xometry API

The Xometry API is more than just a single tool; it’s a suite of specialized services designed for modern manufacturing workflows. Each component offers unique value to engineers and developers.

At its core is the xometry quoting api, a powerful engine for getting real-time pricing on custom parts. This service functions as both an instant quoting api and a custom parts quoting api, capable of analyzing 3D CAD files and returning detailed price and lead time information across dozens of manufacturing processes and materials.

Perhaps one of its most innovative features is the dfm feedback api. This tool goes beyond pricing to provide automated Design for Manufacturability analysis on your CAD models. By flagging potential issues that could make a part difficult or expensive to produce, this design for manufacturing api helps engineers optimize their designs before a single chip is cut, saving significant time and money.

Beyond the Code: Other Essential Design Resources

Xometry’s commitment to empowering engineers extends well beyond software tools. The company provides a wealth of educational content and practical guides to help designers at every stage of the product development lifecycle.

These resources include:

- Comprehensive Design Guides: Detailed guides on best practices for CNC machining, 3D printing, sheet metal fabrication, and more.

- Material Selection Tools: In-depth information and comparison tools for hundreds of manufacturing materials, from plastics to exotic metals.

- Webinars and Case Studies: Expert-led sessions and real-world examples that provide valuable insights into manufacturing technologies and industry trends.

- Finishing Services Guide: A complete overview of available finishing options, such as anodizing, powder coating, and plating, to ensure your parts meet their final specifications.

These materials are an invaluable part of the Xometry ecosystem, helping designers make informed decisions and create parts that are optimized for both function and manufacturability. By combining these resources with the API and CAD add-ins, you can leverage the full power of an on-demand manufacturing api and knowledge base to bring your projects to life.

Frequently Asked Questions

What is the Xometry API used for?

The Xometry API is primarily used to integrate Xometry’s instant quoting, DFM feedback, and ordering capabilities directly into custom software applications, such as internal procurement portals, ERP/PLM systems, or e-commerce platforms.

How do I get a Xometry API key?

You can get a Xometry API key by registering on the official Xometry Developer Portal. After signing up, you will be issued a unique key to authenticate your application’s requests.

Are Xometry’s CAD add-ins free to use?

Yes, Xometry’s add-ins for SOLIDWORKS, Autodesk Inventor, and Autodesk Fusion 360 are free to download and use. They allow you to get instant quotes and DFM feedback directly within your design environment.

Can the API provide manufacturability feedback?

Absolutely. The API includes a dedicated DFM feedback API endpoint that analyzes your 3D models and returns specific, actionable feedback to help you optimize your design for manufacturing, potentially reducing cost and production time.