In the fast-paced world of engineering, product development, and manufacturing, speed and accessibility are paramount. Traditional manufacturing methods, while powerful, often come with long lead times and high setup costs, especially for one-off parts or small batches. This is where the world of digital manufacturing has created a paradigm shift, and at the forefront of this revolution is Xometry.

This guide provides a comprehensive look at Xometry 3D printing services, exploring how this powerful platform connects creators, engineers, and businesses with a vast network of manufacturing capabilities. Whether you’re a startup looking to create your first physical prototype or a large enterprise needing production-grade components, understanding how to leverage a service like Xometry is a modern necessity. We’ll cover everything from how the platform works to the specific technologies and materials at your disposal.

Table of Contents

- What is Xometry? A Digital Manufacturing Powerhouse

- How Does Xometry Work? The Instant Quoting Engine

- A Deep Dive into Xometry’s Additive Manufacturing Technologies

- Exploring the Vast Library of Xometry Materials

- Key Applications: From Rapid Prototyping to Production Parts

- Xometry Review: Understanding the Competitive Landscape

- Frequently Asked Questions

What is Xometry? A Digital Manufacturing Powerhouse

So, what is Xometry? At its core, Xometry is a global digital manufacturing platform that leverages a massive, distributed network of over 10,000 manufacturing partners to produce custom parts on demand. Think of it as an intelligent marketplace that connects customers who need parts made with the machine shops and manufacturing facilities that have the capacity and capability to make them.

This model moves manufacturing away from the constraints of a single factory floor and into the cloud. By using AI-powered software to instantly price parts and match jobs with the best-suited partner, Xometry streamlines the entire procurement process. While the company offers a wide range of services including CNC machining and injection molding, it has become a go-to resource for 3D printing.

How Does Xometry Work? The Instant Quoting Engine

The genius of the platform lies in its simplicity and speed, which directly answers the question, "how does Xometry work?" The entire process is centered around the proprietary Xometry instant quote engine. This tool removes the days or weeks of back-and-forth communication typically required to get a quote from a traditional machine shop.

Here’s a breakdown of the typical workflow:

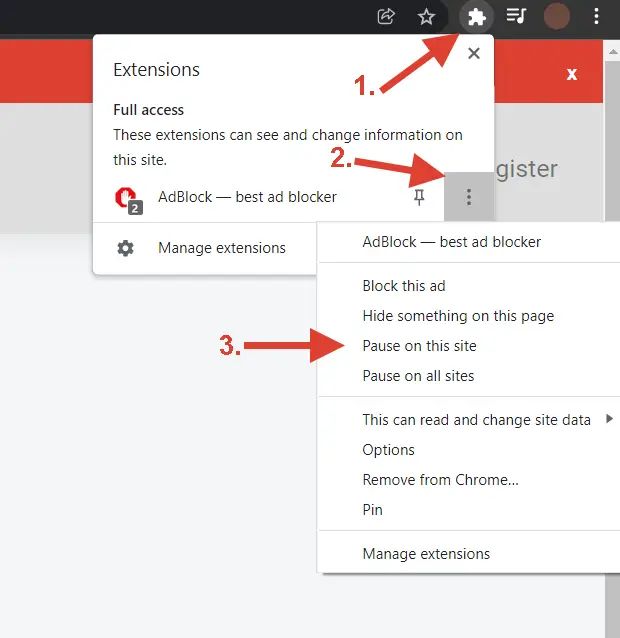

- Upload Your 3D CAD File: The process begins when you upload your design file (formats like STEP, STL, and SLDPRT are all supported) directly to the Xometry website.

- Configure Your Part: You then select your desired manufacturing process—in this case, a specific type of 3D printing. You’ll also choose your material, finish, and quantity. The platform provides real-time design-for-manufacturability (DFM) feedback, highlighting potential issues that could impact cost or production.

- Receive an Instant Quote: Within seconds, the AI-driven engine analyzes your part’s geometry and specifications to generate a comprehensive quote. This analysis is key to determining Xometry pricing, as it considers factors like material cost, machine time, and part complexity.

- Place Your Order: If you’re happy with the price and lead time, you can place your order with a single click. Xometry then handles all the logistics, assigning your job to a vetted partner in its network and managing the project through to delivery and quality assurance.

A Deep Dive into Xometry’s Additive Manufacturing Technologies

Xometry offers an extensive range of additive manufacturing technologies, making it a versatile online 3D printing service for nearly any application. Each process has unique strengths, making it suitable for different materials and end-uses.

Here are some of the core technologies available:

- FDM Printing (Fused Deposition Modeling): This is one of the most common and cost-effective 3D printing methods. It works by extruding a thermoplastic filament layer by layer to build a part. It’s an excellent choice for basic proof-of-concept models and low-cost prototypes where dimensional accuracy isn’t critical.

- SLA Printing (Stereolithography): SLA printing uses a UV laser to cure liquid resin into hardened plastic. This process is known for producing parts with extremely fine details, tight tolerances, and a very smooth surface finish, making it ideal for presentation models and form-and-fit testing.

- SLS Printing (Selective Laser Sintering): For strong, functional parts, SLS printing is a top choice. It uses a high-powered laser to fuse nylon-based powder together. Because the unfused powder supports the part during printing, SLS doesn’t require dedicated support structures, allowing for complex internal geometries.

- MJF 3D Printing (Multi Jet Fusion): Developed by HP, MJF 3D printing is another powder-bed fusion technology known for its speed and excellent mechanical properties. It produces high-density parts with a slightly finer surface finish than SLS, making it a popular choice for both functional prototypes and end-use components.

- DMLS (Direct Metal Laser Sintering): For projects requiring the strength and durability of metal, DMLS is the leading technology. This sophisticated process uses a fiber laser to sinter metal powder, creating fully dense metal parts from materials like aluminum, stainless steel, and titanium. This makes metal 3D printing accessible for demanding aerospace, automotive, and medical applications.

Exploring the Vast Library of Xometry Materials

A key advantage of using Xometry is the sheer variety of Xometry materials available. Their selection covers a wide spectrum of plastics, metals, and elastomers, ensuring you can find the right material with the right properties for your project.

- Plastic 3D Printing: This is the largest category, with options for every major technology. Common choices include versatile thermoplastics like ABS and PLA for FDM; high-detail resins for SLA; and durable nylons (like PA 12) for SLS and MJF.

- Metal 3D Printing: The selection of metals is robust, catering to high-performance industrial needs. Materials like Aluminum AlSi10Mg, Stainless Steel (316L), and Titanium (Ti64) are regularly used for lightweighting, high-strength applications, and parts that need to withstand extreme temperatures.

- Elastomers and Composites: Xometry also offers flexible, rubber-like materials (TPU) for applications requiring impact absorption or pliability, as well as composite materials reinforced with carbon fiber or glass for parts needing exceptional stiffness and strength.

Key Applications: From Rapid Prototyping to Production Parts

The flexibility of Xometry’s platform supports the entire product development lifecycle. Its capabilities are broadly used for two primary purposes:

First is rapid prototyping. The ability to get a physical part in hand in a matter of days is a game-changer for design iteration. Engineers and designers use Xometry for prototypes to test form, fit, and function, allowing them to identify design flaws early and accelerate their time to market.

Second, and increasingly common, is 3D printing for production parts. Advances in materials and technology have made additive manufacturing a viable option for low-to-mid volume production runs. This is especially true for complex parts that are difficult or impossible to manufacture traditionally. As a leader in industrial 3D printing, Xometry provides the quality control and scalability needed to use 3D-printed components as final, end-use parts. This type of on-demand manufacturing eliminates the need for expensive tooling and reduces inventory waste.

Xometry Review: Understanding the Competitive Landscape

When evaluating any service, it’s helpful to provide an objective Xometry review and understand its place in the market. Xometry’s primary strength is its marketplace model, which provides massive, scalable capacity and an unparalleled range of manufacturing options in one place. The instant quoting engine is a significant differentiator, saving users immense time and effort.

Of course, there are also strong Xometry alternatives. When comparing Xometry vs Protolabs, the key difference is the business model. Protolabs primarily operates its own large-scale manufacturing facilities, giving it direct control over the production process. In contrast, Xometry’s partner network model provides greater flexibility and technology breadth.

In a comparison of Xometry vs Shapeways, the distinction often comes down to the target audience. While both are powerful platforms, Shapeways has historically catered more to individual creators, designers, and small businesses, whereas Xometry has built its reputation on serving the more demanding needs of industrial, engineering, and enterprise customers. Choosing the right service ultimately depends on your specific project requirements, volume, and material needs.

Frequently Asked Questions

How much does Xometry 3D printing cost?

The cost is determined on a per-part basis by the Xometry instant quote engine. Pricing depends on several factors, including the 3D printing technology used, the material selected, the volume of the part, its overall complexity, and the desired lead time.

What file types can I upload to Xometry?

Xometry accepts a wide variety of 3D CAD file formats. The most common and preferred formats include STEP (.stp, .step), STL (.stl), SOLIDWORKS (.sldprt), and IGES (.igs, .iges).

Is Xometry good for custom 3D printing?

Yes, custom 3D printing is the foundation of Xometry’s business. The platform is designed specifically to produce custom parts based on a customer’s unique digital design files, offering services for quantities from a single piece to thousands.

What is the typical lead time for an order?

Lead times vary depending on the chosen technology, material, and part complexity. The instant quoting tool provides an estimated lead time along with the price, with options for both standard and expedited delivery.

Can I get a single prototype made?

Absolutely. Xometry’s on-demand manufacturing model is perfectly suited for producing single prototypes, making it an invaluable tool for rapid prototyping and design validation.